|

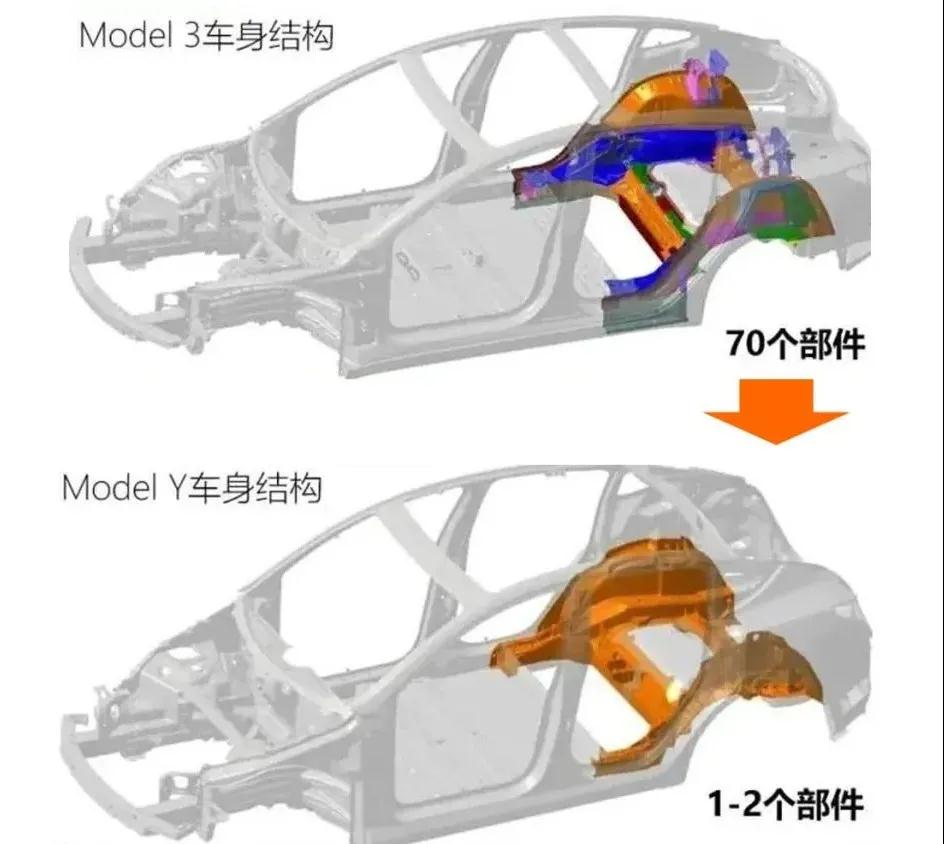

Tesla leads the car body revolution, reducing 70 parts to one!

(2021/2/24) In February, Tesla shared its Model Y production line at the Shanghai Super Factory. What is different is that a super large 6000Ton die-casting machine is installed in the production line, which can produce large-scale automobile die-casting parts. The original 70 parts have been successfully combined into two large parts, and they will even be combined into one in the future. Tesla CEO Musk claimed that this will be "a revolution in car body engineering."

An engineering perspective from Tesla shows that: Compared with the 70 parts required for Model 3, the entire bottom of Model Y consists of only 2 parts:  The body will be drastically reduced from 70 parts to 1-2 casting parts, the body chassis will be reduced in weight, the welding process will be streamlined, and the complexity will be simplified, which can better improve product consistency. The capital expenditure for all robots to assemble these parts will be significantly reduced, and the production cycle will be shorter, making it more suitable for mass production. The production efficiency of the die-casting process is high. The high-speed and high-pressure filling can hydraulically insert the metal into the model in a short time, and can produce parts with complex shapes, clear outlines, and thin-walled deep cavities. Ningbo Hongxin is specialized in designing and manufacturing die casting parts, plastic injection parts and CNC parts, our professional team is ready for providing solution for your Challenging project. |