|

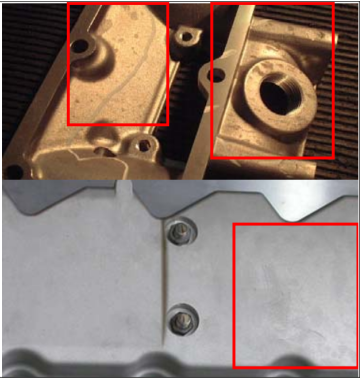

Analysis of defects in die castings -Oil Marks

(2020/5/3) Defect description: spots on the surface of the casting are different from the base metal, generally formed by coating carbide or punch oil

cause: 1. Paint splashes onto the surface of the casting 2. The position and time of the oil injection of the punch is incorrect 3. During the operation of the process, oil or water splashes on the surface of the casting Improve methods: 1. After opening the mold, first take out the casting and perform a circular action 2. Do not spray the punch oil directly into the pouring port 3. Protection during process operation During the production of aluminum alloy die-casting parts, pay more attention to the changes in the details of the die-casting mold and die-casting machine, and take good methods as a habit, and the quality will be guaranteed. Ningbo Hongxin Precision Machinery Co., Ltd. is a professional manufacturer of die casting, prototype, injection molded parts and CNC parts, welcome to contact us to discuss project development. |