|

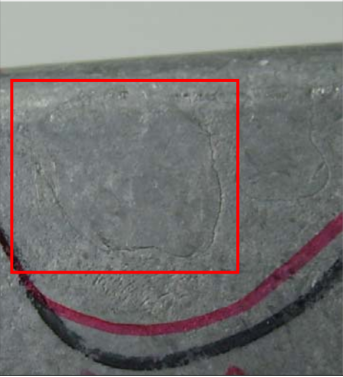

Analysis of defects in die castings - cold shut

(2020/4/24) Defect description: The gap between the lower temperature metal streams that meet each other but are not fused, is irregularly linear, there are two kinds of penetration and non-penetration, under the action of external forces have a tendency to develop.

Causes. 1. Lower liquid temperature and lower mold temperature 2. The composition of the alloy does not meet the standard liquidity difference 3. Poorly filled metal liquids 4. Irrational gate design and long process 5. Low filling speed or poor exhaust Methods of improvement. 1. Increase the temperature of the liquid or mold 2. Change the alloy composition 3. Improve the filling direction of the inner gate 4. Change the location or cross-sectional area of the gate or increase the overflow 5. Increase pressure injection speed Ningbo Hongxin Precision Machinery Co., Ltd. is a professional manufacturer of die casting, prototype, injection molded parts and CNC parts, welcome to contact us to discuss project development. |